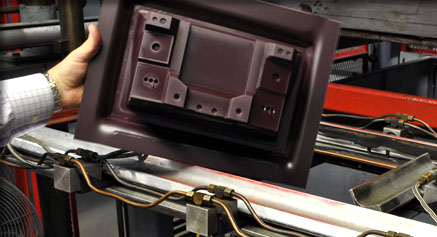

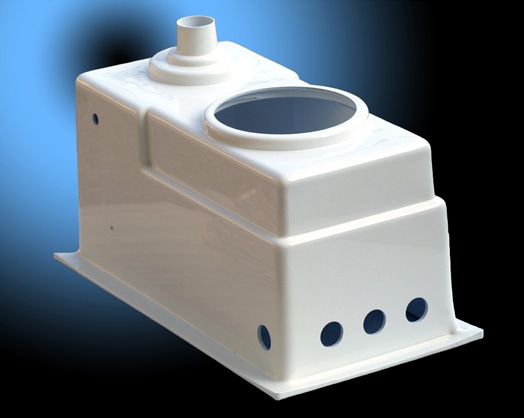

Specializes in supplying custom molded highly engineered plastic parts manufactured by the thermoforming processes of vacuum pressure and twin sheet forming.

Trimming vacuum formed parts.

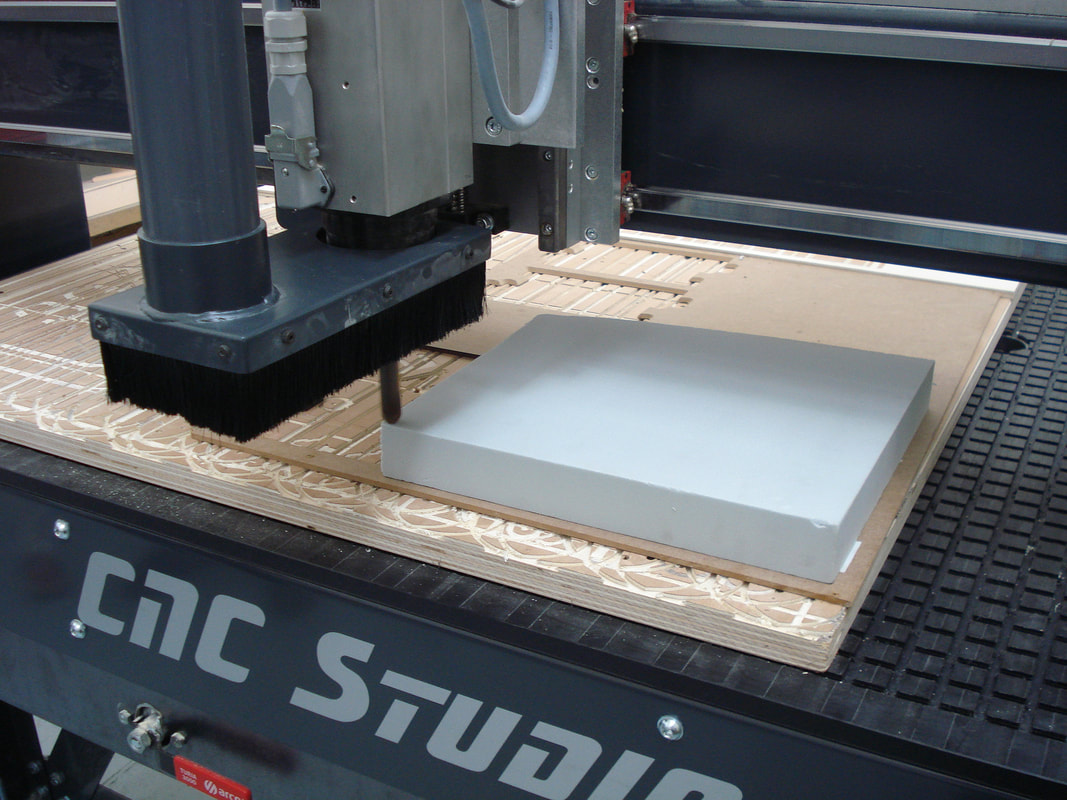

The ft10 features a 15mm thick mdf work surface whilst the.

Robotic solutions inc.

It is often used when manufacturers need to save time and reduce production costs.

Trimming with a robot.

For more on popular vacuum forming trimming methods head over to formech s website.

Vacuum forming trimming machine round duration.

Thermoforming is a generic term for the process of forming plastic parts from a flat sheet using vacuum or pressure.

Our cnc machines trim parts of up to 2000x1000mm.

This gives you room to trim.

When combined with advance finishing techniques pressure forming results in products comparable to those formed by injection molding.

Vacform group invest heavily in the latest cad cam technology.

Ideally suited for education design and prototype packaging applications formech s ft series offers simple and safe trimming of vacuum formed parts.

Five state of the art 5 axis cnc routers with the latest offline 5 axis trimming software installed on site.

The cost of tooling and capital equipment is much lower in vacuum forming thermoforming than many competing processes.

With additional capabilities including polishing deburring and slot cutting the ft series is a highly versatile and cost effective trimming and finishing solution.

Has established a reputation as an industry leader in expanding the viability of the.

How can vacuum forming impact overall part cost.

Excellent video of using a robot to trim mill plastic vaccum formed parts duration.

5 axis cnc routers are used to trim complex vacuum formed parts.

Plastic vacuum forming is not especially complicated but it does take some practice to understand the finer points of building and forming.

Thermoforming offers close tolerances tight specifications and sharp detail.